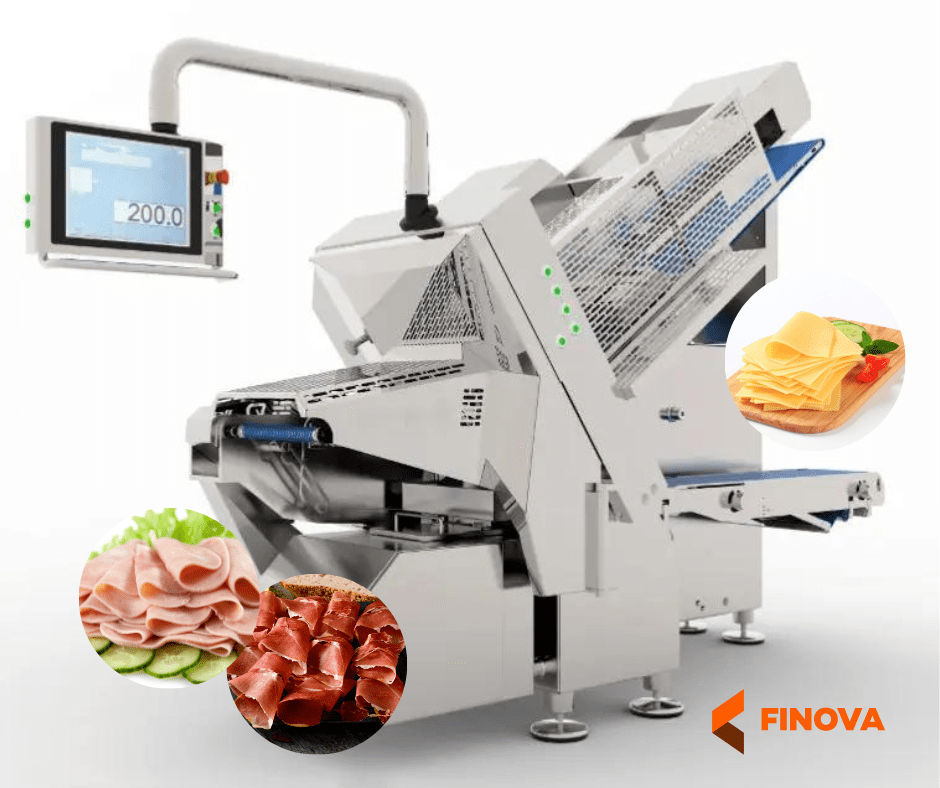

When slicing irregularly shaped products such as bacon, precision and efficiency are essential. This is where 3D perimeter scanning becomes a revolutionary tool, allowing precise calibration of portions to ensure maximum weight accuracy in each package.

This innovative system scans the contour of irregular parts, allowing the number of cuts per package to be adjusted according to the shape of the part and ensuring uniform distribution from the beginning to the end of the process.

How does 3D perimeter scanning work?

The 3D perimeter scanning system is designed to calculate the actual volume of irregularly shaped products and calibrate portions in real mode.

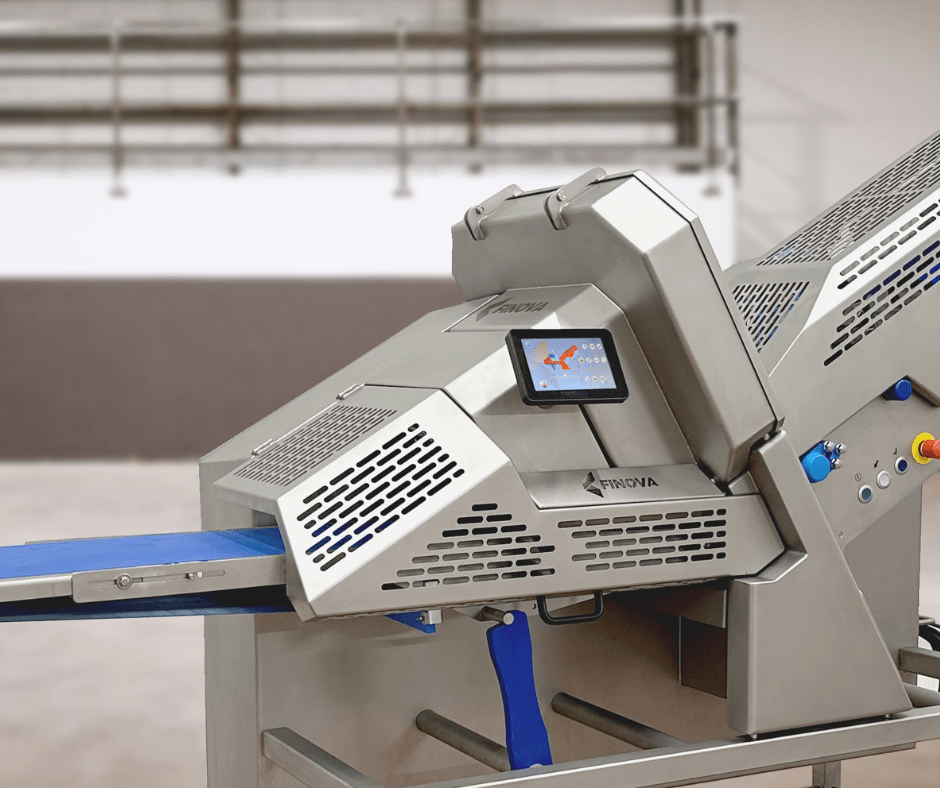

It consists of several key elements:

- a 3D reconstruction system,

- a scale,

- a processor,

- and a product movement system.

These components work in synchronization with the rest of the slicing line, transmitting precise commands to the slicer to ensure accurate portion weights.

One of the most outstanding features of this system is its ability to determine the weight of each “virtual slice” of the product to be sliced in 0.1 mm increments. Under standard conditions, the product is processed at a constant density specified by the operator, or by unit weight.

For the correct calculation of the volume of the processed unit, a laser perimeter reading system, duly calibrated and configured, including 3 independent cameras, is used.

Benefits

The use of 3D perimeter scanning in the food industry offers multiple benefits, including:

- Accuracy in weight: ensuring that each portion of slices has maximum weight accuracy.

- Efficiency in production: optimizing the slicing process and allowing a higher production in less time.

- Adaptability: offering flexible solutions for different types of food with irregular shapes such as bacon or other pieces without the need for pressing.

At FINOVA, we are committed to innovation and excellence, and 3D perimeter scanning is a clear example of how technology can improve efficiency and quality in the food industry.

For more information, please contact us!