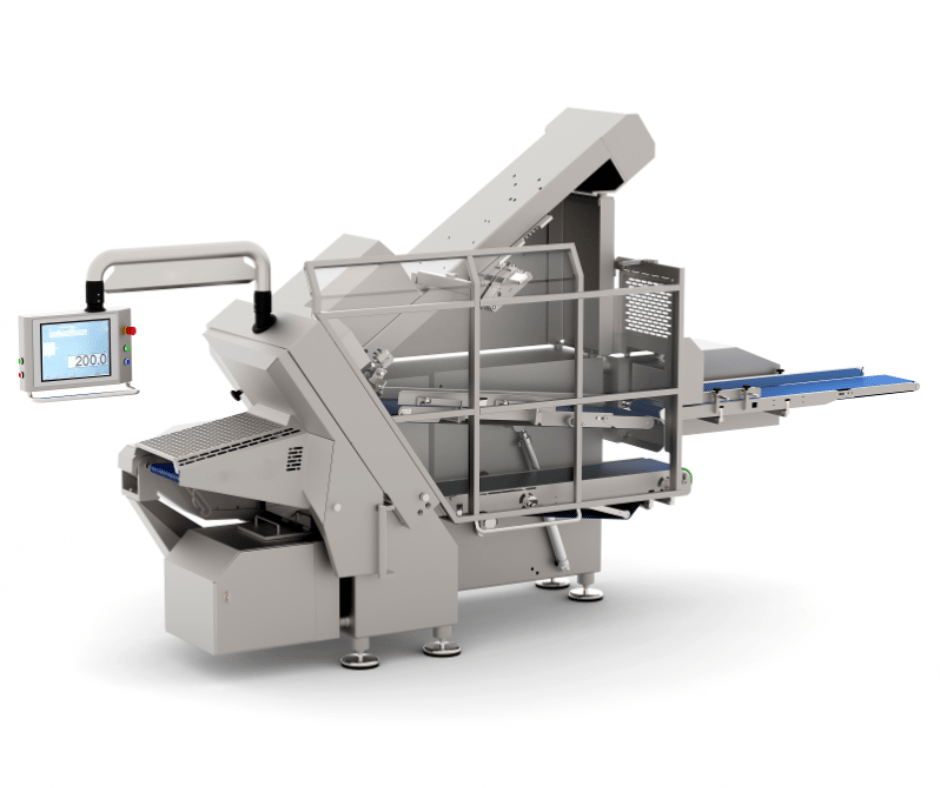

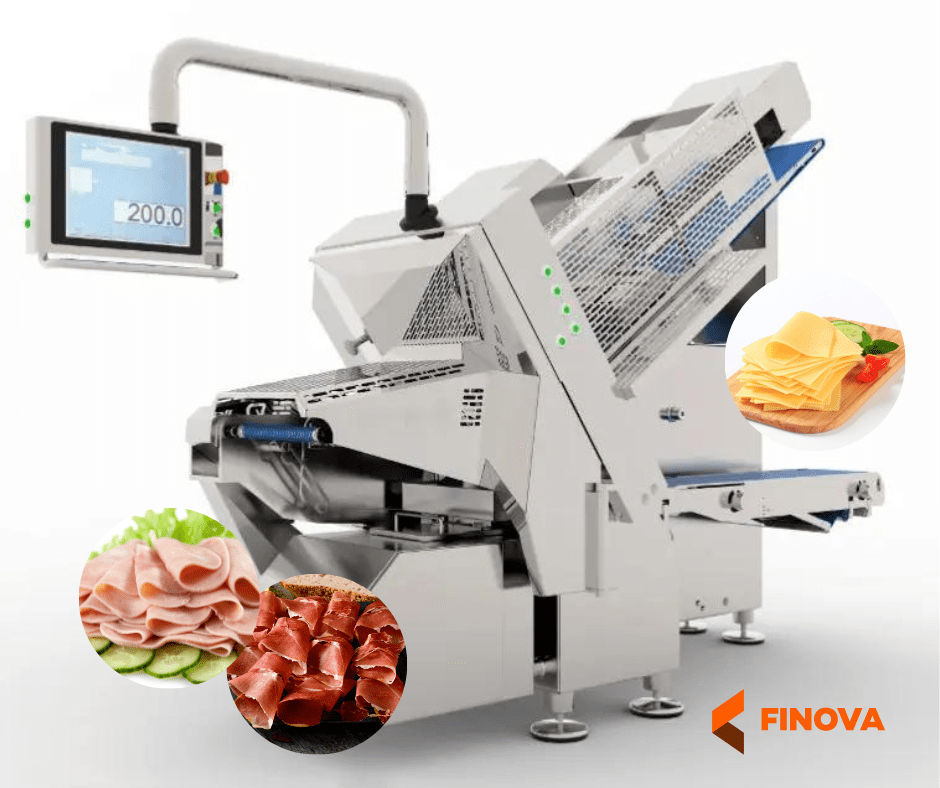

The food industry, especially the sausage, ham and cheese industry, requires machines that offer efficient, accurate and fast solutions. The SliceFil 650 slicer emerges as an outstanding solution for large production industries, promising to revolutionize the slicing and portioning process.

Functionality and Mode of Use

The SliceFil 650 slicer offers unparalleled versatility. Product loading can be done manually or automatically. Once loaded, special tongs are used to move it towards a circular blade. The product is cut with great precision and placed in different presentations, either in stacked portions, staggered batches, or other presentations, on a synchronized feed outfeed conveyor.

Outstanding Features

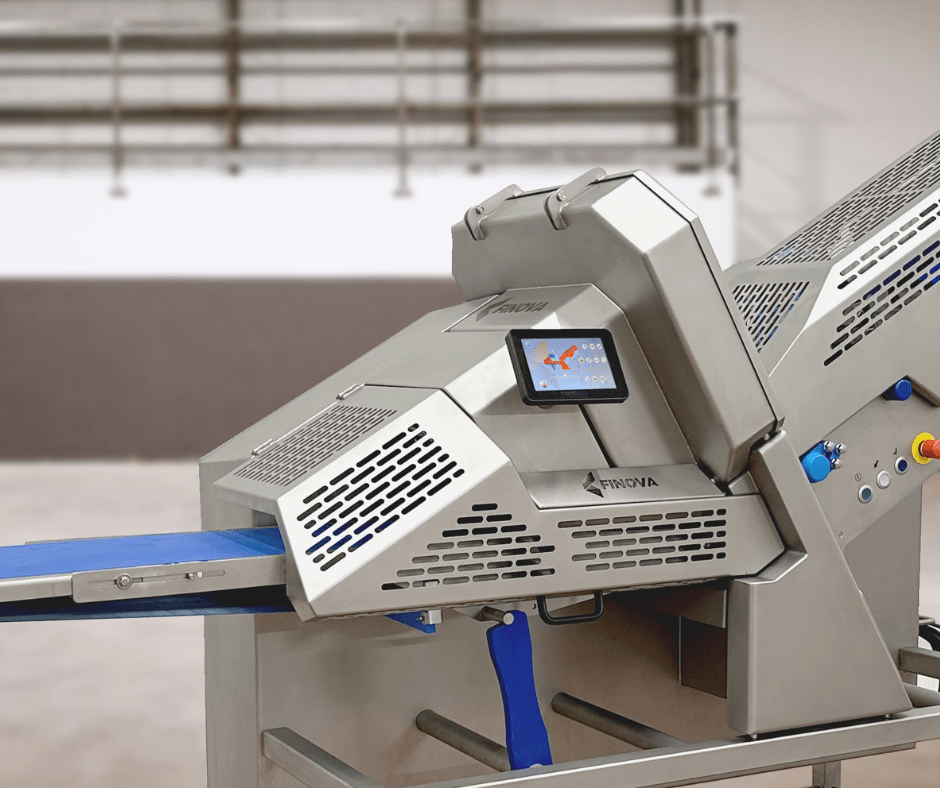

- Robust construction: Manufactured in AISI-304 stainless steel, it guarantees durability and resistance.

- Regulatory compliance: The machine has been built in accordance with the European Directive 2006/42/EC, which ensures its quality and safety.

- Variety in slicing: Multiple portioning designs can be produced, allowing the number of slices and portion length to be adjusted according to specific needs.

- State-of-the-art technology: Incorporates an orbital and circular rotary cutting system, along with independent speed control to ensure a precise cut.

- Intuitive operation: Thanks to the 15″ touch screen on the control panel, all parameters can be easily adjusted.

- Efficient feeding: It has an automatic rear loading system, capable of feeding products up to 1200mm in length.

- Maximum precision: It has a system for detecting and auto-correcting incomplete packages, ensuring that each cut meets the desired specifications.

In short, the SliceFil 650 slicer combines innovation, precision and efficiency to meet the most demanding requirements of the sausage, ham and cheese industry. Its design and features make it an essential tool for any company seeking to maximize production while maintaining quality.