In the food industry, efficiency and precision are crucial, especially when it comes to products such as cheese or sausages. This is where automatic thermoformer discharge of the sliced product to the thermoformer becomes an essential solution. This system is designed to automatically feed cheese or sausage portions into the packaging system, increasing productivity and maintaining high quality standards.

How does the automatic thermoformer unloading system work?

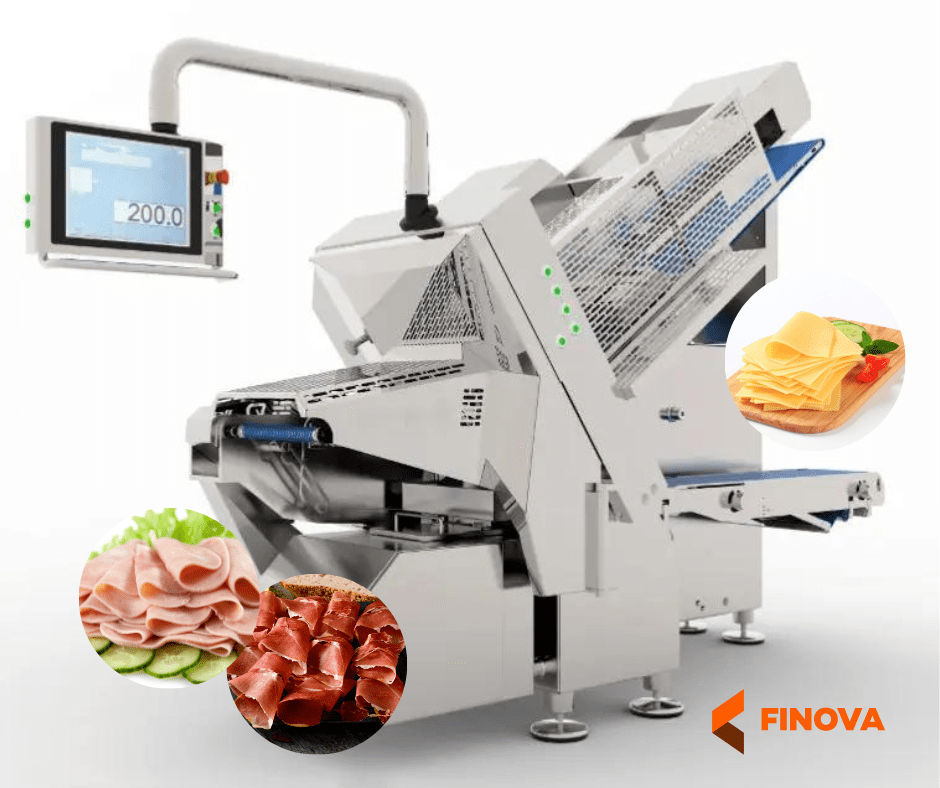

The system is designed to feed portions of cheese and/or meat products automatically into the packaging system. It consists of a set of conveyors that allow the separation, grouping, forming and synchronized unloading of sliced packages into the thermoformer. The system is customized, depending on the customer’s specific needs in terms of production, portion design and thermoforming machine formats.

Customization according to requirements

Each industry has its own specific needs, and the automatic thermoformer discharge system adapts to these needs. Depending on the customer’s production, portion design and thermoformer formats, the system is customized to meet these unique specifications. This flexibility ensures that each customer gets the most effective solution for their operations.

System characteristics

Features of the conveyor system for automatic portion discharge to thermoformer for slicers of the SliceFil range:

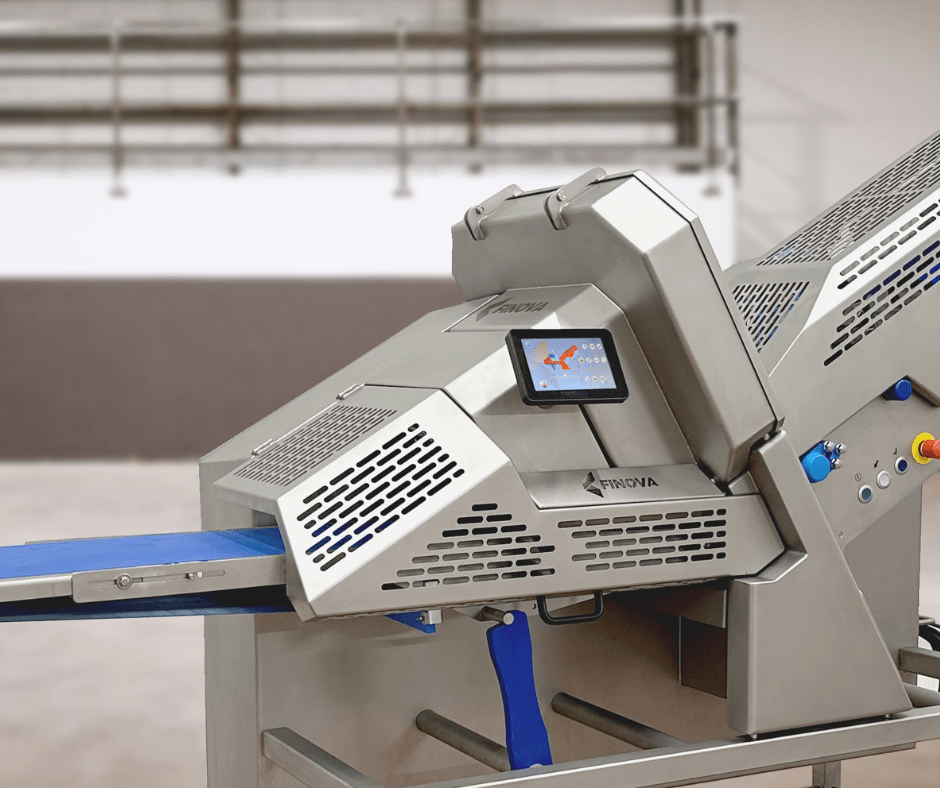

- Equipped with sensors for synchronization between slicer and thermoformer, as well as its own software.

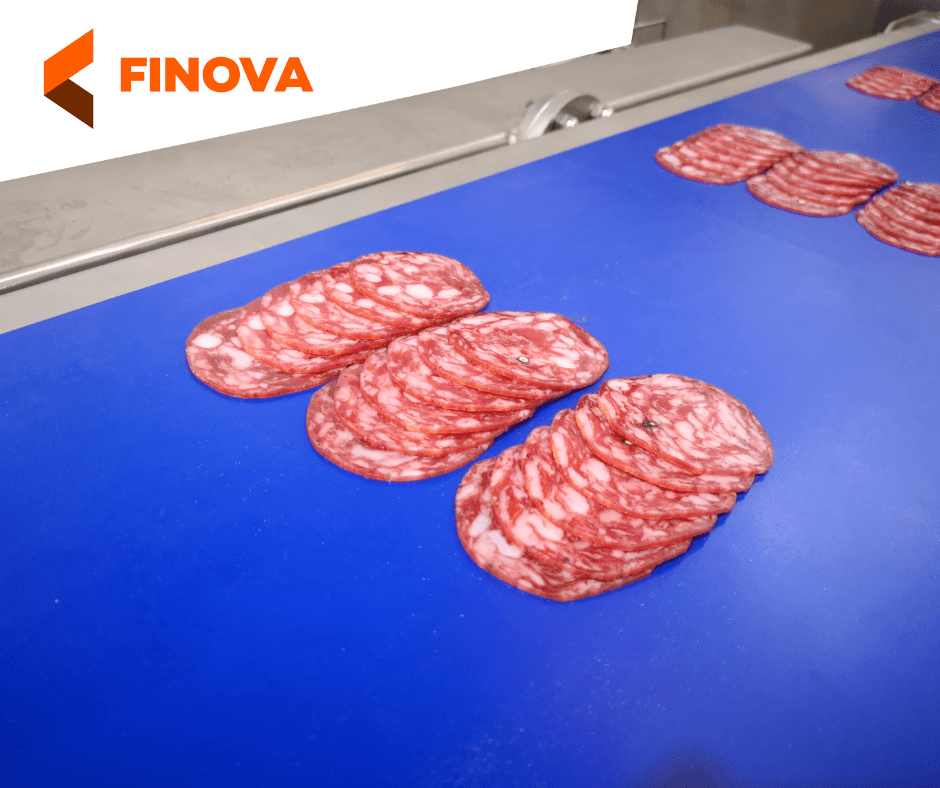

- Blue conveyor belts.

- Chassis built in stainless steel AISI-304.

- Optionally, it can be equipped with a portion misalignment system.

System Technical Data

The system also excels in its technical aspects:

- Number of programs stored in memory: up to 100.

- Working line width: customized.

- Total power: customized.

In conclusion, the automatic thermoformer unloading of sliced product is a revolutionary solution in the food industry, offering customization, efficiency and advanced technology to meet the needs of cheese and sausage production. With this system, the packaging process becomes more efficient, faster and of high quality.

Contact FINOVA for more information.