SliceFil-620: more precision in the Food Industry

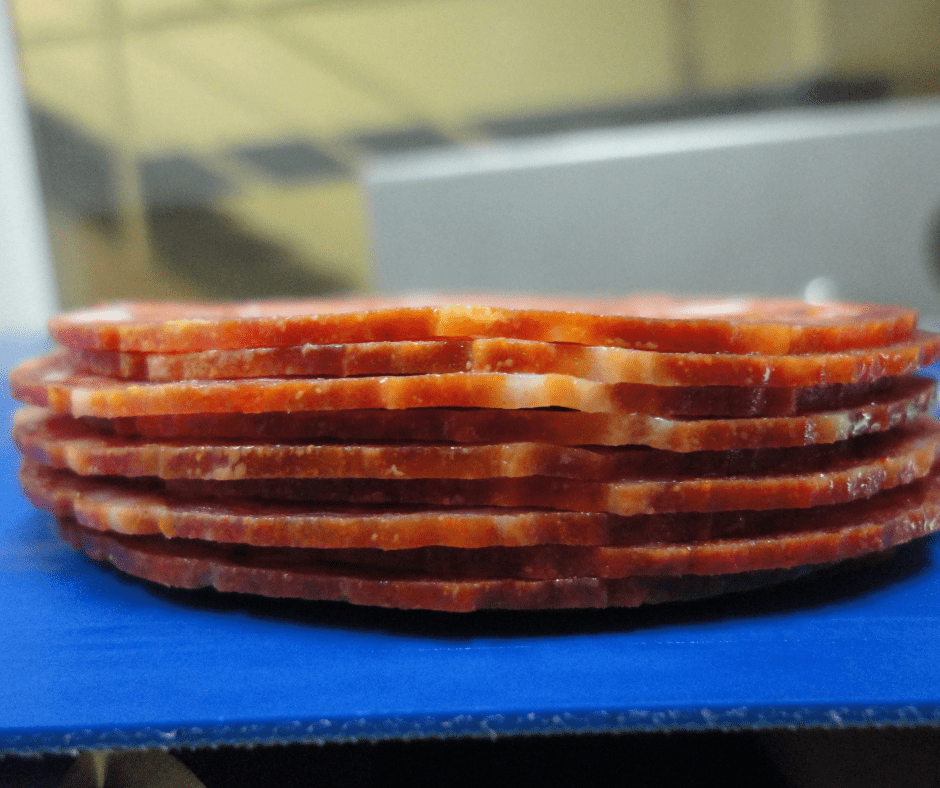

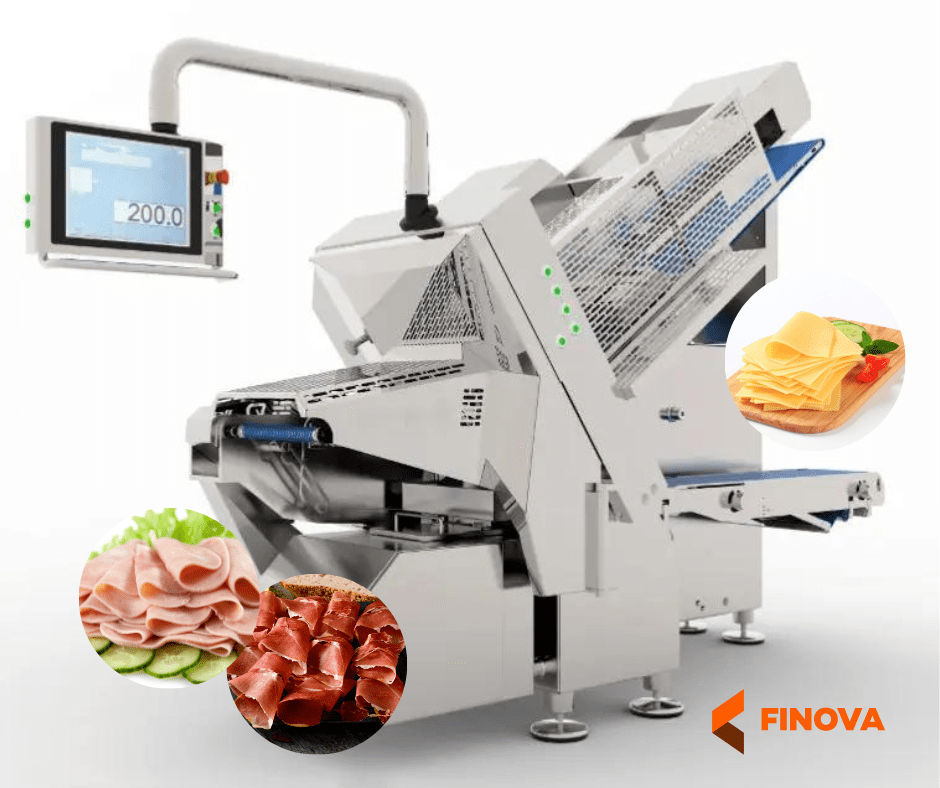

The SliceFil-620 is positioned as a high-performance solution as an automatic slicing system. Its use is essential for large industrial productions involving cheese, sausages and ham. This robust machine is loaded manually, uses grippers to move the product onto a circular blade and then cuts with impressive precision. In addition, it allows placing the slices in stacked portions, staggered batches, among other presentations, which are transferred through a synchronized feed outfeed conveyor.

Innovative and Advanced Features

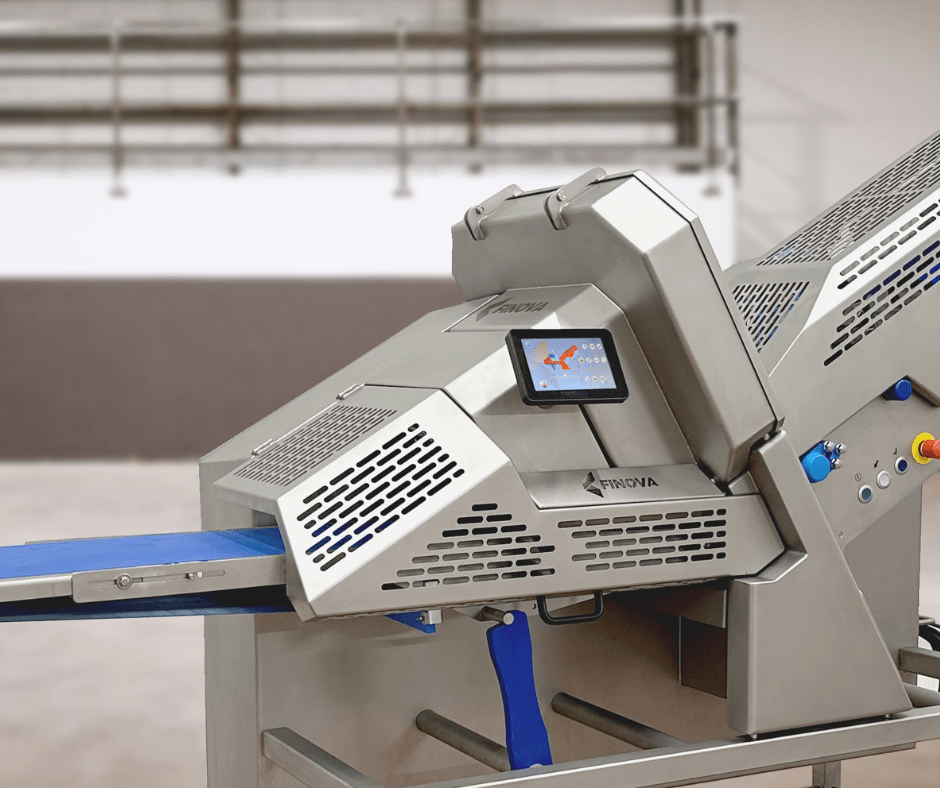

The automatic slicing system of the SliceFil-620 is not only robust, but also made of AISI-304 stainless steel, according to European directives. Its design allows for efficient slicing and stacking of cured or cooked cheeses and sausages. It is also the most versatile, being able to produce a variety of portioning designs, from staggered and stacked to spiral plates and free figures, adjusting the amount of slices in each group according to the customer’s needs.

It also includes an orbital and circular cutting system with independent motors, which allows speed control through the control panel. This intuitive machine facilitates the adjustment of all parameters through a 15-inch touch screen.

Technical Specifications

The dimensions of the SliceFil-620 are 6635x1105x2305 mm and it can cut products up to 1200 mm in length. In addition, the slice thickness can be adjusted from 0.50 to 100 mm. The blade has a diameter of 450 mm and can perform up to 600 cuts per minute, allowing for efficient production.

Customization Options

In conclusion, the SliceFil-620 is an exceptional choice for any food production company looking to improve their automatic slicing system with efficiency and slice quality. This robust, versatile and customizable machine is sure to add value to your slicing process, making you stand out in today’s competitive market.

Contact FINOVA for more information.