Initially, industrial machinery used manual drives with very limited controls. This was a time when human intervention was essential at every step of the production process.

In the 1970s, the introduction of PLCs (Programmable Logic Controllers) marked a revolution. These devices allowed greater flexibility and control in industrial processes, improving efficiency and reducing reliance on manual intervention.

Over time, the Human Machine Interface (HMI) became a vital component. The HMI significantly improved process monitoring and control, allowing operators to interact with the machines more effectively and efficiently, increasing productivity and reducing operational errors.

Industry 4.0

The concept of Industry 4.0 is the new way of producing by adopting digital manufacturing technologies. It is characterized by advanced automation, interconnection of machines and systems, and efficient use of resources. HMI systems in this era not only display information, but also allow users to control and adjust processes in real time.

Advantages of Industry 4.0

- Quality optimization: Automation and digitization allow constant monitoring and precise adjustments, improving the quality of the final product.

- Fast and intuitive programming: The use of icons and simple characters makes programming easy for any operator.

- Control and cost reduction: Operational efficiency and lower margin of error significantly reduce production costs.

- Operational safety: Advanced HMI systems improve safety by enabling better monitoring and control of processes.

- Sustainability: Efficient use of resources and waste reduction contribute to more sustainable production practices.

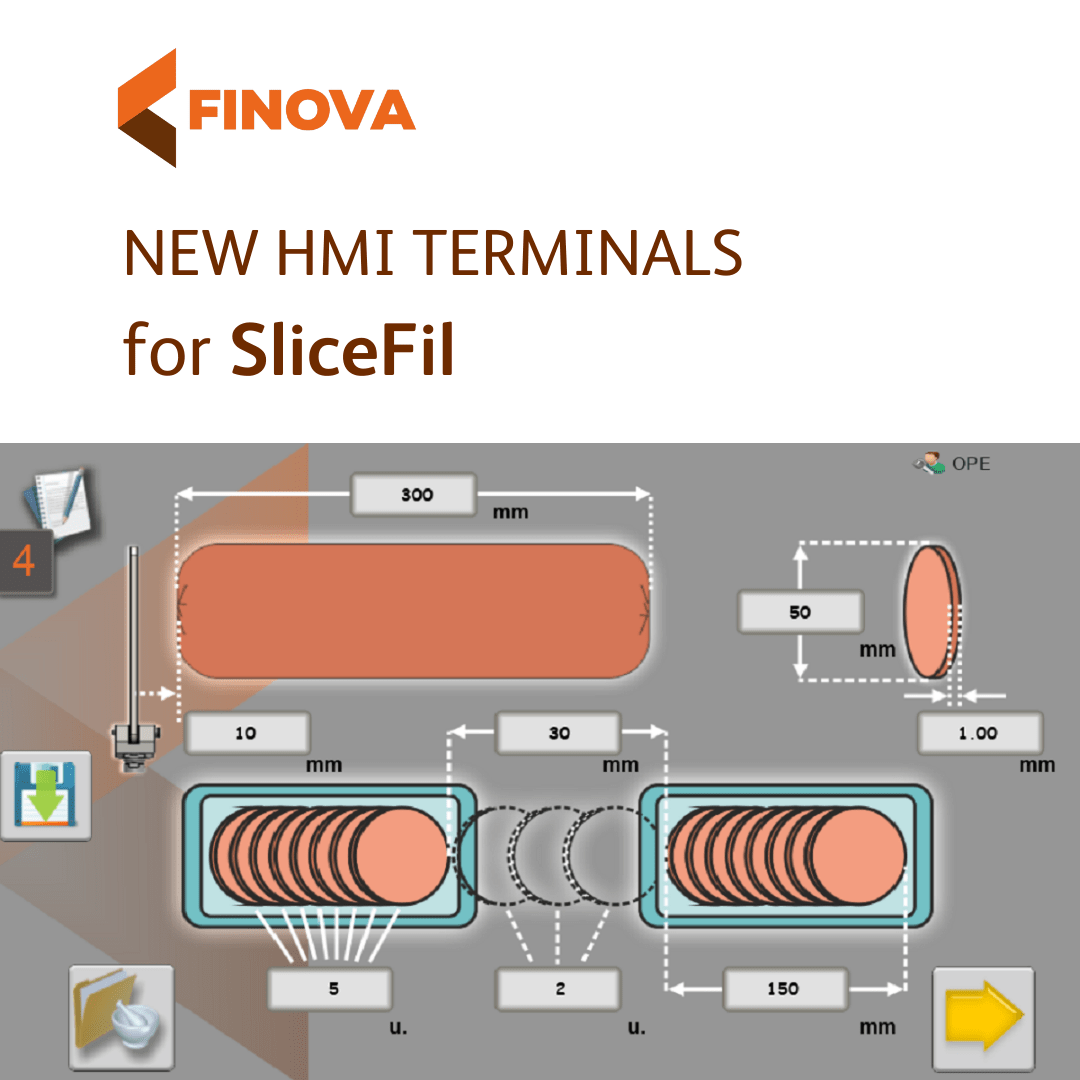

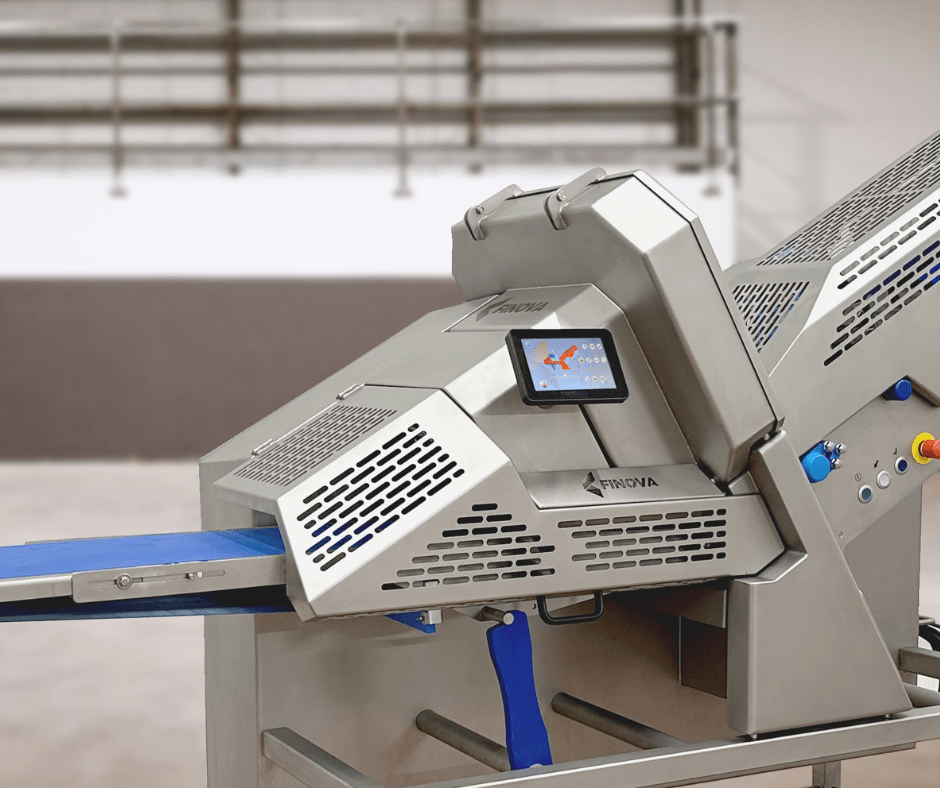

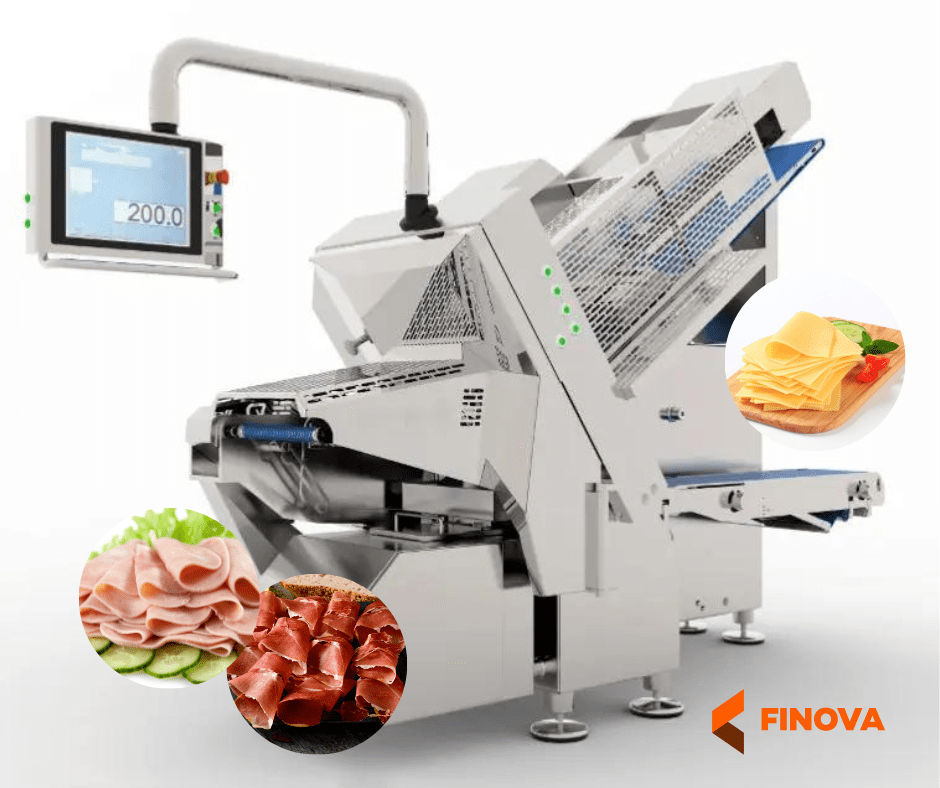

Panasonic HMI terminals on the Finova SliceFil

Intuitivecontrol

Panasonic HMI terminals allow control of all cutting and portion presentation parameters through easy-to-use menus.

Alarm self-diagnostic tools

Our advanced alarm control system provides real-time information on the status of the equipment. This allows operators to identify and solve problems without the need for specialized technical service.

Preventive maintenance

The system reminds operators when to perform the most common maintenance operations, such as blade greasing, and informs them when the time is right for more thorough overhauls.

Remote connection

Our HMI terminals allow remote connection. If you need help, Finova can help you program prescriptions or resolve incidents.

Digitization in the industry, through the implementation of advanced HMI terminals, offers superior performance and unlimited connectivity. The use of Big Data and intelligent technologies improves both processes and products. The gradual implementation of these technologies is key to adapting to new demands and remaining competitive in the market.