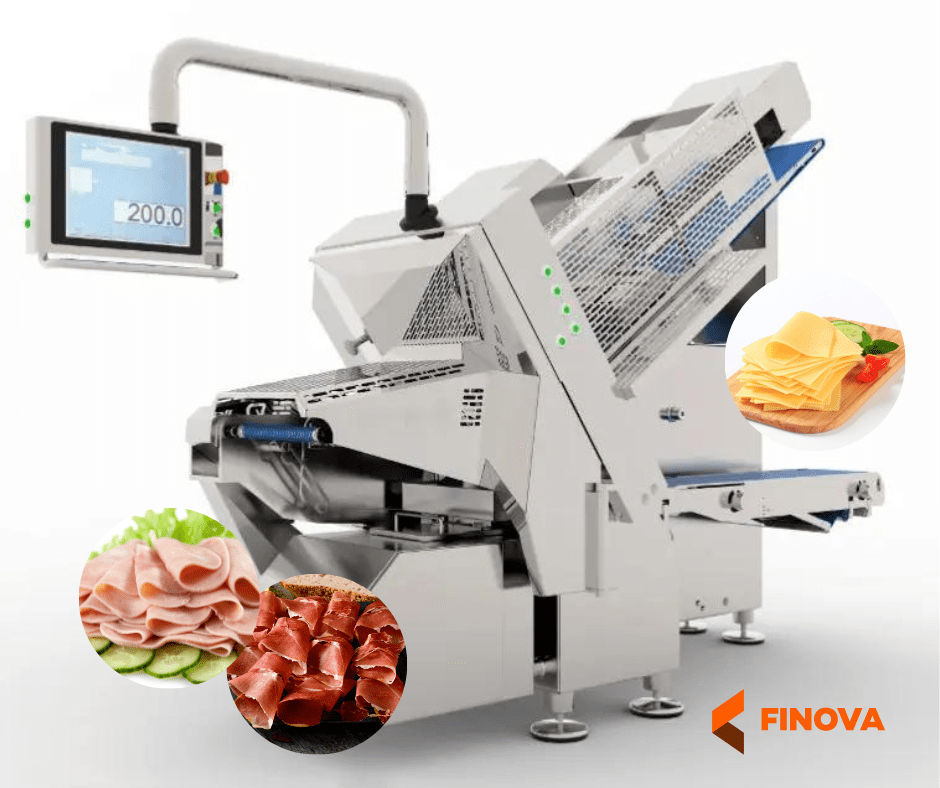

In the food industry, accuracy in the weight of sliced product packages is an essential requirement to guarantee quality, reduce waste and ensure regulatory compliance. In this context, the integration of dynamic weighing systems in slicing systems brings added value to Finova slicers. The dynamic weighing scale allows real-time weight control, automatically adjusting slice thickness without interrupting the production process.

What is dynamic weighing?

Dynamic weighing is a technology that makes it possible to measure the weight of portions while they are in motion, without having to stop the production line. Thanks to this system, it is possible to obtain accurate weight readings without slowing down the pace of work in environments with high production levels.

Operational advantages:

- Real-time weight control.

- Maintenance in the continuity of the process.

- Consistent accuracy at high speed.

Integration of the dynamic weighing scale in Finova slicers

The dynamic weighing scale is fully integrated in our models of slicers, both modular and automatic:

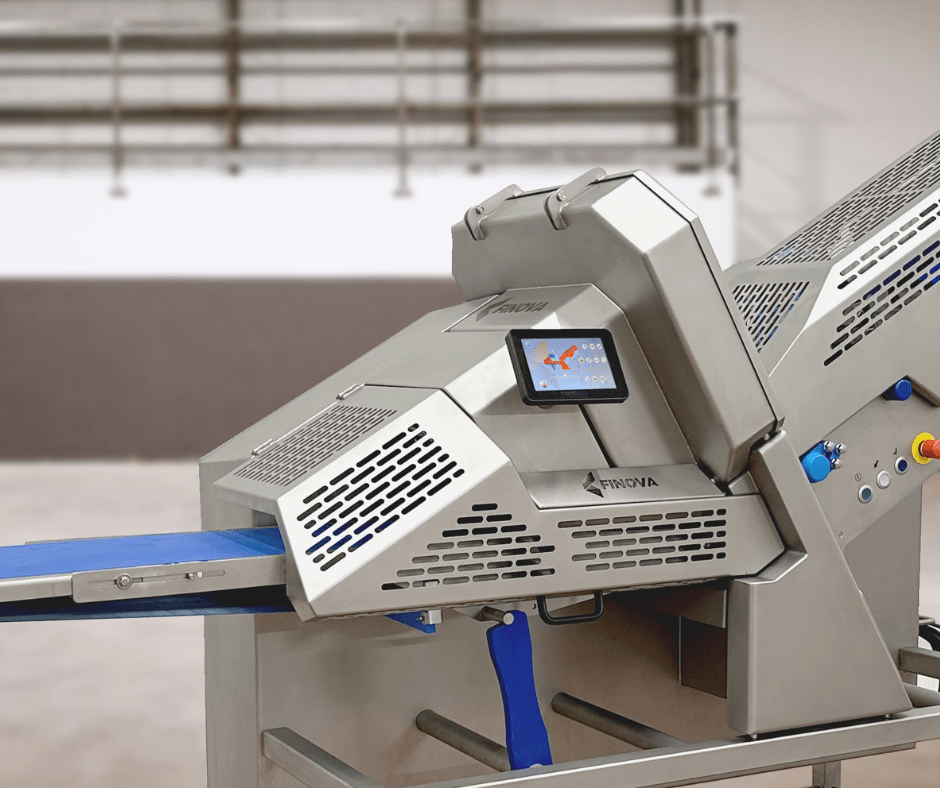

- Modular Slicers: SliceFil-320 / SliceFil-420 / SliceFil-620/625

- Automatic Slicers: SliceFil-650 i SliceFil-660

Main technical characteristics:

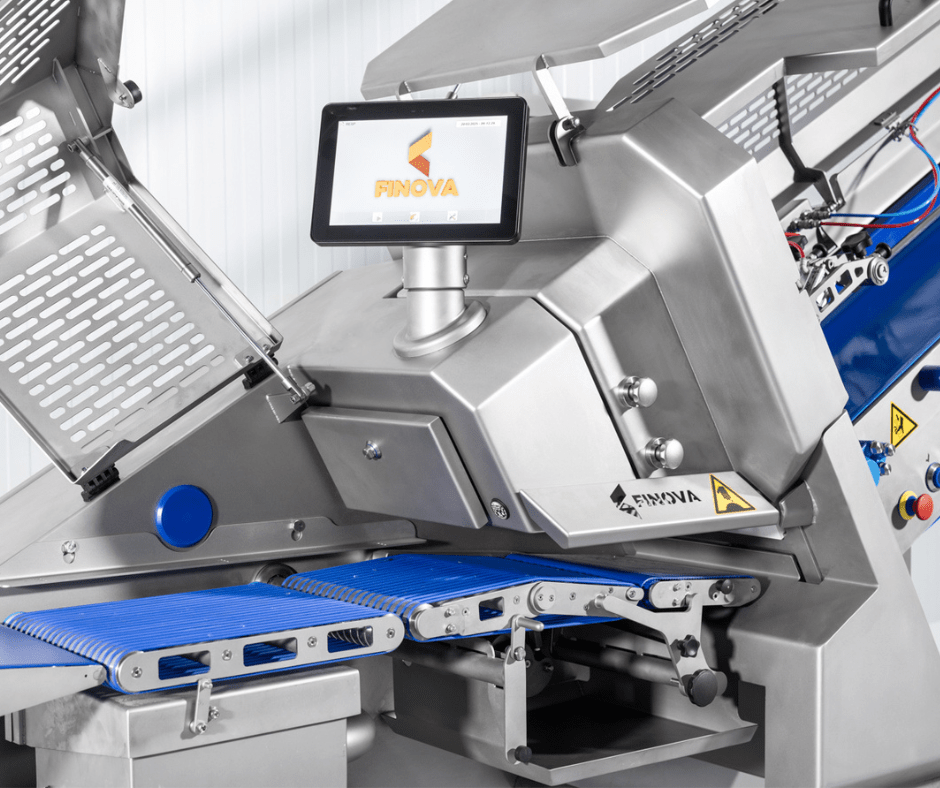

Continuous weight correction

The system automatically regulates the thickness of the slices based on real-time data, ensuring that each package remains within the established weight specifications.

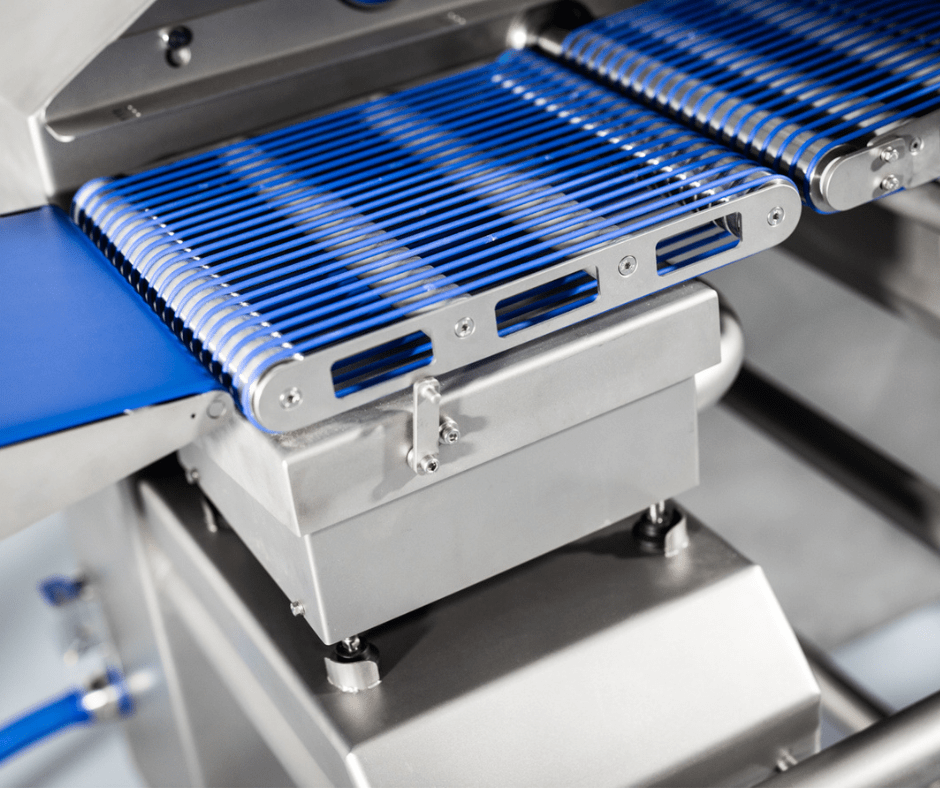

Up to three independent dynamic weighing lanes

The possibility of integrating up to three independent dynamic scales allows a significant increase in productivity, while maintaining individualized weight control.

Intuitive touch interface

The operator can easily configure and control the entire process through the machine’s touch screen. This interface facilitates the adaptation of the parameters according to the type of product or the desired format.

Benefits for the food industry

Waste reduction

Precise weight control reduces the amount of off-spec product, optimizing raw material usage and minimizing losses.

Regulatory compliance

The system ensures that each package meets regulatory weight and labeling requirements.

Improved production efficiency

The production line maintains its speed while maintaining the quality of the final product, which translates into greater operational efficiency.

Flexibility and adaptability

The solution easily adapts to different formats and product types, offering a versatile tool for the food industry.

Added value and competitive advantage

The implementation of a dynamic weighing scale provides added value and competitive advantages in the food industry, improving quality control.

If you are looking to improve operational efficiency, reduce waste and guarantee the quality of the final product, at Finova we offer slicing solutions adapted to the requirements of the sector. For more information on how to incorporate a dynamic weighing scale in your production process, please contact our technical team. We will be happy to advise you.