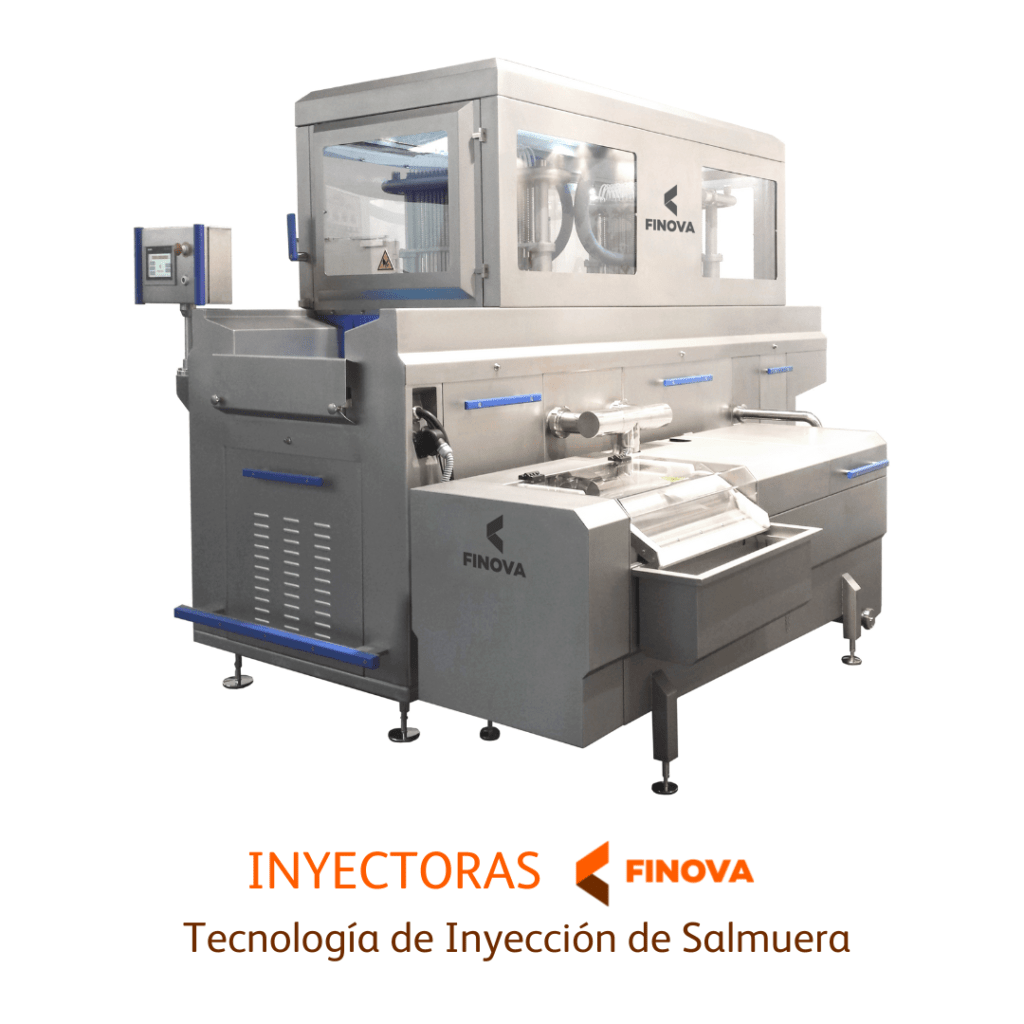

Brine injectors for meat are essential equipment in the meat industry, since they make it possible to improve the texture, flavor and preservation of products through controlled brine injection. FINOVA stands out in the meat injection process thanks to its high-pressure brine injection system, which guarantees uniform and efficient distribution.

In the following, we will explain in detail the general features and benefits of FINOVA injectors.

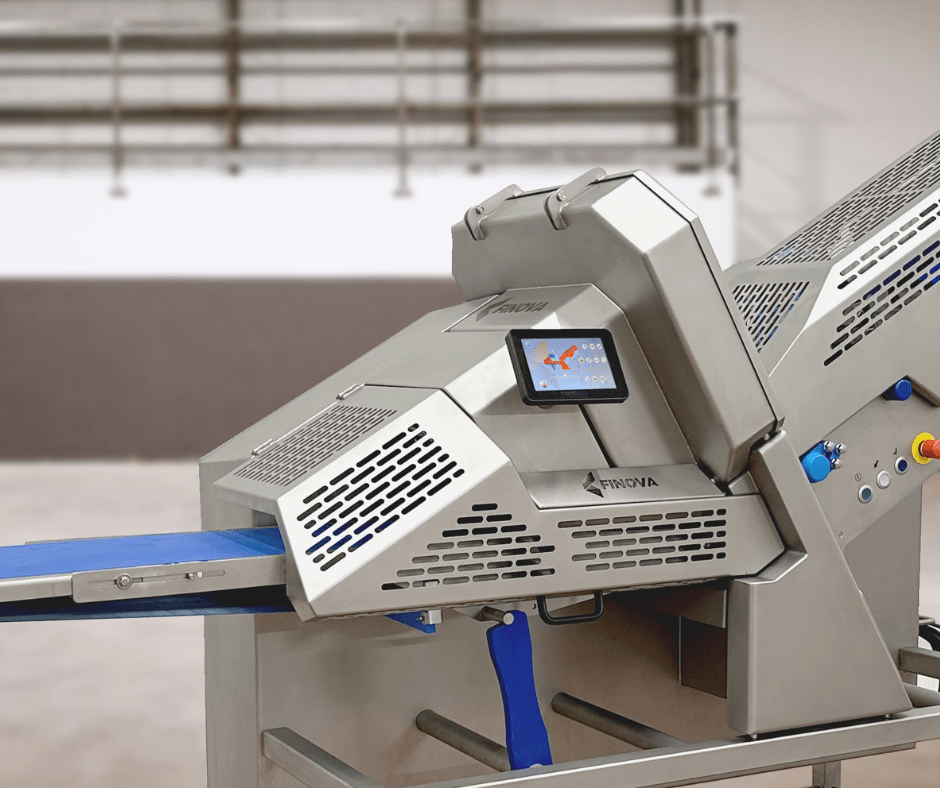

FINOVA Injector Characteristics

FINOVA injectors are designed to optimize brine injection in bone-in and boneless meat products.

Injector models:

- Single head injectors with 30 or 50 needles.

- Double head injectors with 100 needles.

FINOVA’s injection technology creates a multiple and dispersed nebulizing spray effect inside the muscle, achieving optimum brine distribution and high injection with high production. In addition, it guarantees uniformity in color, flavor and texture of the final product. The models can be configured to process both bone-in and boneless products, adapting to the diverse needs of the meat industry.

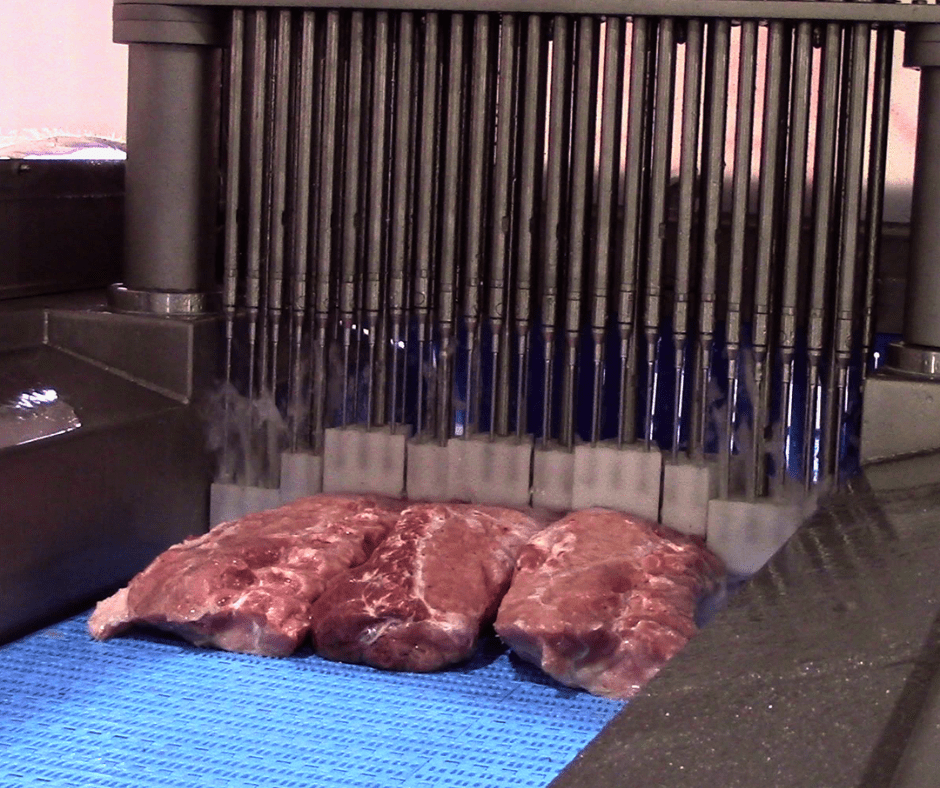

How does the injection system work?

The injection system works by introducing brine into the meat through a needle system, ensuring uniform distribution inside the muscle. The brine, composed of water, salt and additives, improves the texture, flavor and preservation of the product.

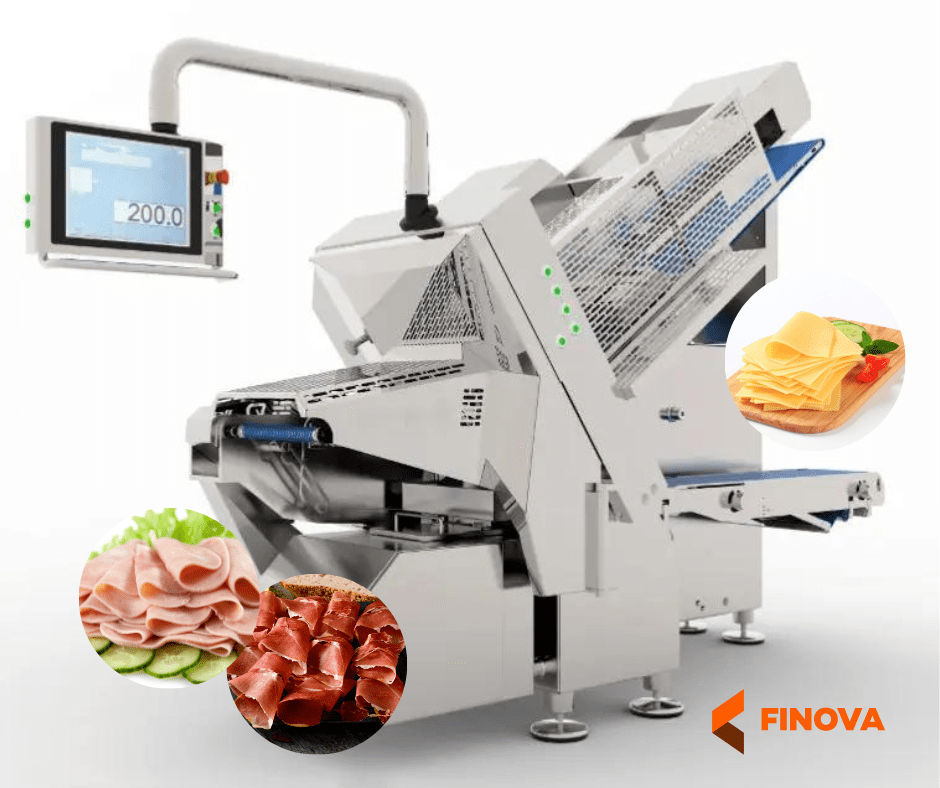

This process is ideal for all types of meat products with or without bone:

- Ham, loin, bacon, chops.

- Chicken, turkey, breasts, knuckle.

FINOVA Injector Technology

FINOVA injectors are equipped with a volumetric pump, a hydraulic system that allows greater power and precision in each injection cycle.

Advantages of the hydraulic system

The homogeneous distribution of the brine throughout the meat piece guarantees a uniform process, while the system offers greater efficiency and durability compared to conventional systems.

Nebulizing Spray Effect

One of FINOVA’s most outstanding innovations is its injection system based on a nebulizing spray effect, which allows a uniform and dispersed injection inside the meat muscle.

This is achieved by means of the hydraulic pump that ensures uniform pressure on all needles.

In addition, having more injection points per pass improves brine distribution, making it possible to achieve high injection percentages in a single application.

Another key factor is the size of the needle perforations, which varies between 0.6 and 0.8 mm, in contrast to the perforations of more than 1 mm of other machines, which allows better brine retention and less liquid loss.

Filter System

To guarantee the purity and stability of the brine, FINOVA incorporates an advanced 3-phase filtration system, which allows the injection of low and high density brines.

To further optimize the process, an optional brine temperature maintenance system (double refrigerated jacket) can also be integrated to preserve the brine’s properties and improve the quality of thefinal product.

Benefits of the FINOVA Injection System

FINOVA injectors offer a number of key advantages for the meat industry:

Increased efficiency: FINOVA’s injection technology guarantees a more homogeneous and dispersed injection into the muscle, ensuring that the brine is evenly distributed throughout the piece, which improves the quality and consistency of the final product.

Better brine retention: thanks to the atomization produced by high-pressure injection (spray effect), the brine remains inside the meat, minimizing losses due to meat draining. This translates into greater profitability for producers.

Ideal for marinated products: FINOVA injectors are especially effective for marinated products such as whole chicken, chops, fresh meat and bacon.

More powerful and durable system: The hydraulic pump system does not require maintenance as usual as centrifugal pumps (seals, bearings, etc.).

Technical characteristics of Brine injectors for meat

FINOVA meat brine injectors are designed with technical features that optimize process efficiency:

- Strategically placed injection points for uniform distribution.

- Adjustable injection rate: Between 15% and 90% in a single pass.

- Head with needles and retractable retainers.

- Conveyor feed with electronically adjustable pitch.

- Non-slip plastic modular belt conveyor for greater safety.

- Advanced brine filtration, by means of:

- Self-cleaning rotary drum.

- Two plate filters and suction filter.

- Brine tank with agitator to maintain homogeneity of the mixture.

- Quick connection and disconnection of needles by means of push-button connections.

- Transparent protections that allow visual control of the injection process.

- Hydraulic cylinder actuation for greater efficiency and precision.

In short, FINOVA meat brine injectors guarantee efficient and homogeneous injection of meat products. Thanks to their hydraulic system, their nebulizing spray effect and their advanced filtering system, they ensure optimum quality in each application.

Contact us to learn more about the solutions we can offer you and boost your production, we are ready to advise you!