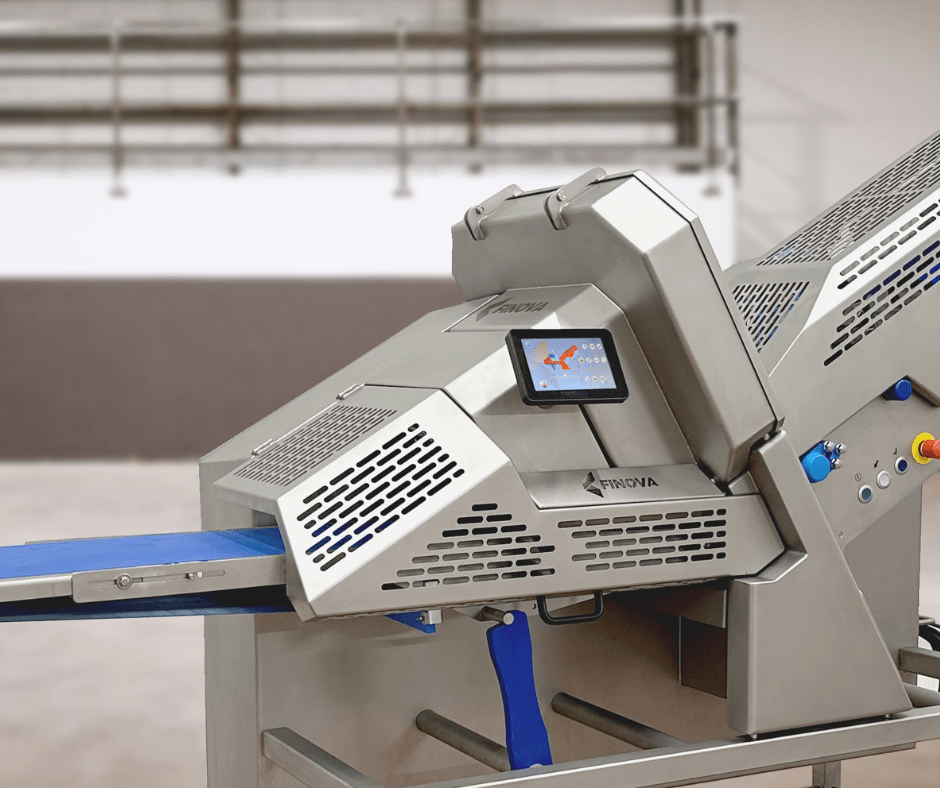

In the competitive world of the food industry, heat treatment during the cooking process of meat products makes the difference in achieving an exceptional product. Finova’ s cooking ovens represent the technological vanguard in the heat treatment of meat products, combining innovation, efficiency and versatility in an integral solution that transforms the way of cooking or smoking at the industrial level.

What are Finova baking ovens?

These are chambers for cooking or smoking food products, specifically designed to optimize the cooking of meat products. However, this machinery goes much further than a simple oven: they are intelligent systems that precisely control each variable of the cooking process.

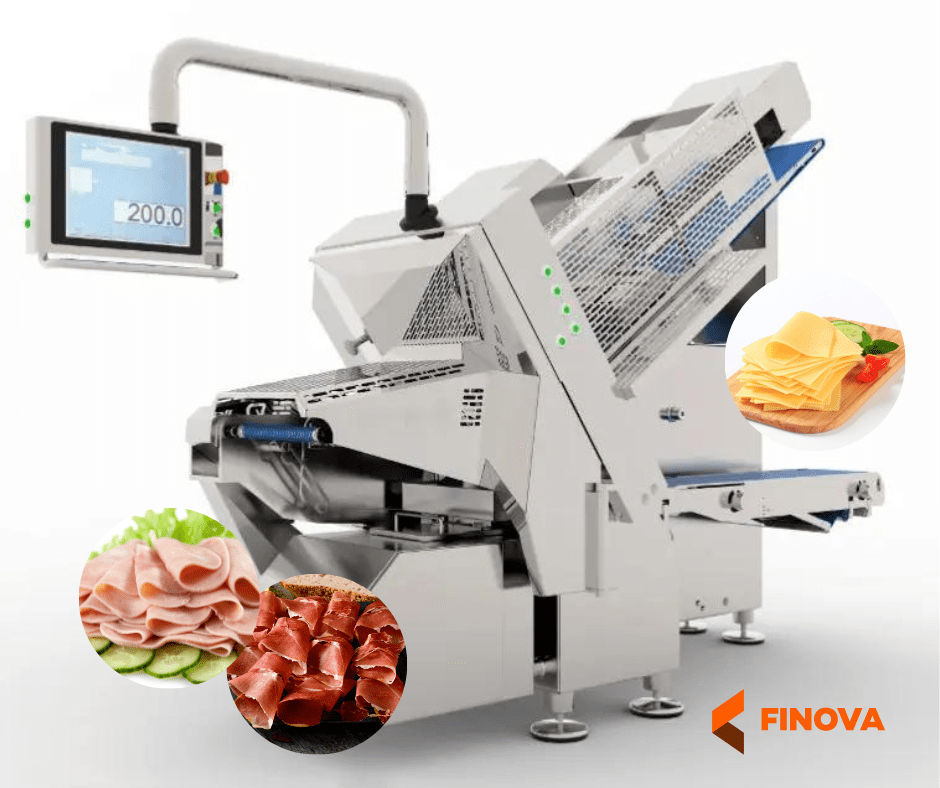

They are specially designed to process a wide range of products, mainly meat products:

- Sausages

- Longanizas

- Cooked ham

- Bacon

- Chops

The multiple possibilities of recipes and types of baking, together with the optimization of the air flow distribution in the oven, allow a high uniformity and efficiency in this process.

Types of ovens adapted to every need

Direct steam cookers

These ovens use moist heat as the main cooking method, ideal for cooked or unsmoked products such as cooked ham, bacon or frankfurters.

Main characteristics

- Direct steam cooking.

- Controlled humid heat environment.

- Perfect for cooked and unsmoked products.

Direct steam cooking ensures that products maintain their natural moisture while reaching the required food safety temperature.

Universal ovens

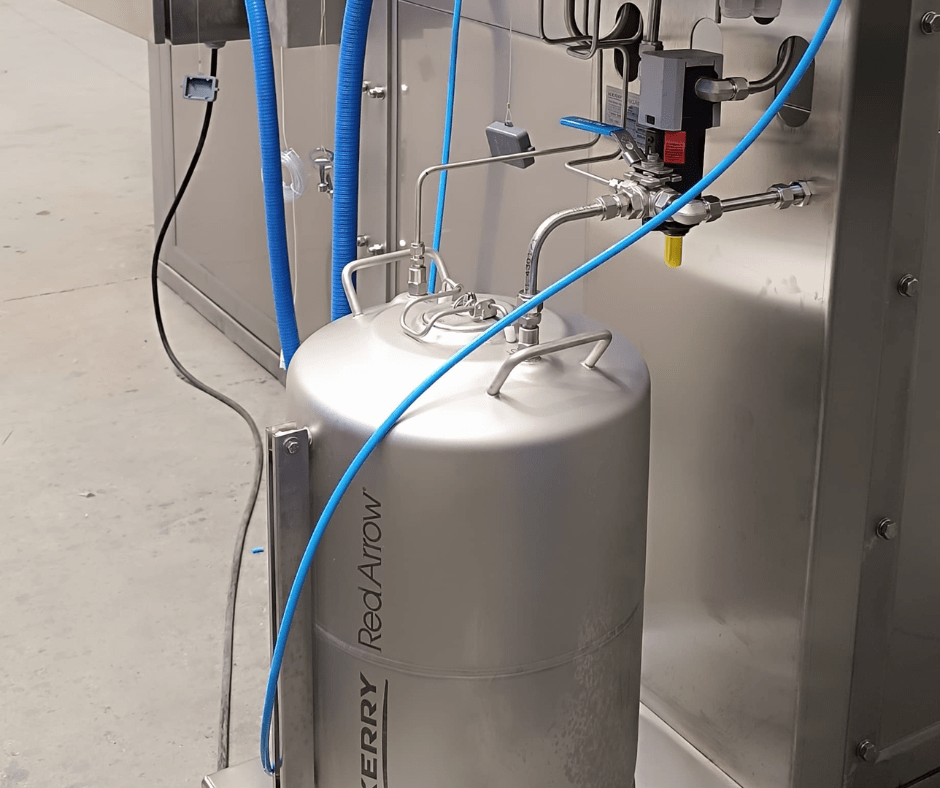

Finova’s universal ovens combine direct steam and coil heat, offering the flexibility to work with both moist heat and dry heat according to product needs:

Advanced capabilities

- Dual system of moist heat + dry heat.

- Possibility of incorporating natural or liquid smoking systems.

Applications

- Sausages that require cooking + drying.

- Products with optional smoking processes.

This versatility allows the product portfolio to be expanded without the need for additional equipment.

Innovative technical features

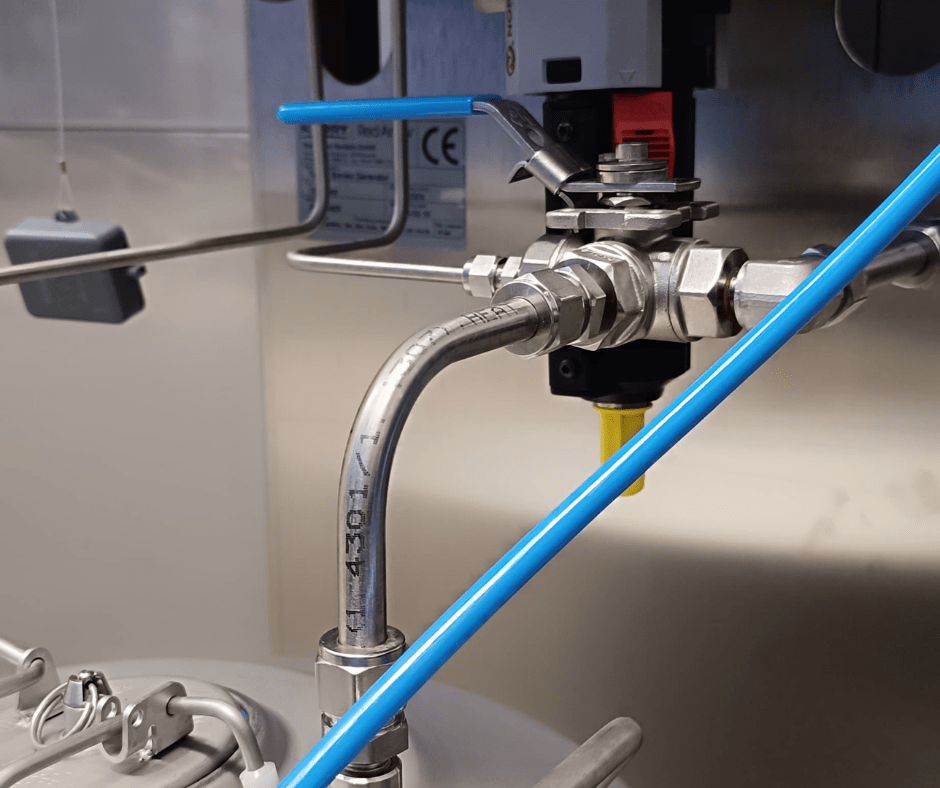

The heating resides in its dual heating system:

- Direct steam connection (0,5 – 1 Bar) and/or

- Steam with heating coil (8 Bars)

Exclusive air recirculation system in the interior:

The most outstanding innovation is the exclusive air recirculation system:

- Powerful suction and impulsion turbine.

- Synchronized opening dampers to distribute the flow from left to right alternately, thus achieving uniform cooking temperatures for all the products introduced in the oven.

Intelligent process control

- Large capacity of processes and programmable recipes.

- Two temperature probes: chamber and product core.

- Possibility of spraying water from the network for rapid cooling of the product.

- Automatic cleaning circuit with soap dosing.

- High quality thermal insulation for improved energy efficiency.

Tailor-made adaptation and personalized advice

Tailor-made adaptation

Each baking oven is specifically adapted to:

- The particular needs of each client.

- The specific requirements of each product.

Additional advisory service

- Finova goes beyond the sale of baking ovens, offering:

- Additional technology consulting service at the customer’s premises.

- Understanding the customer’s specific needs.

- Testing and development of recipe improvements.

Finova baking ovens: the smart choice

The kilns for firing of Finova are a strategic investment in quality, efficiency and competitiveness. They combine advanced technology, personalized service and adaptability for companies seeking excellence in meat processing.

At Finova we understand that each client has unique needs and that technology must adapt to those needs. Our commitment is focused on being your technology partner, committed to the success of your business.

Are you ready to take your meat processing to the next level?

For more information on cooking ovens that can transform your production process, contact our sales team. Excellence in meat processing begins with choosing the right equipment.