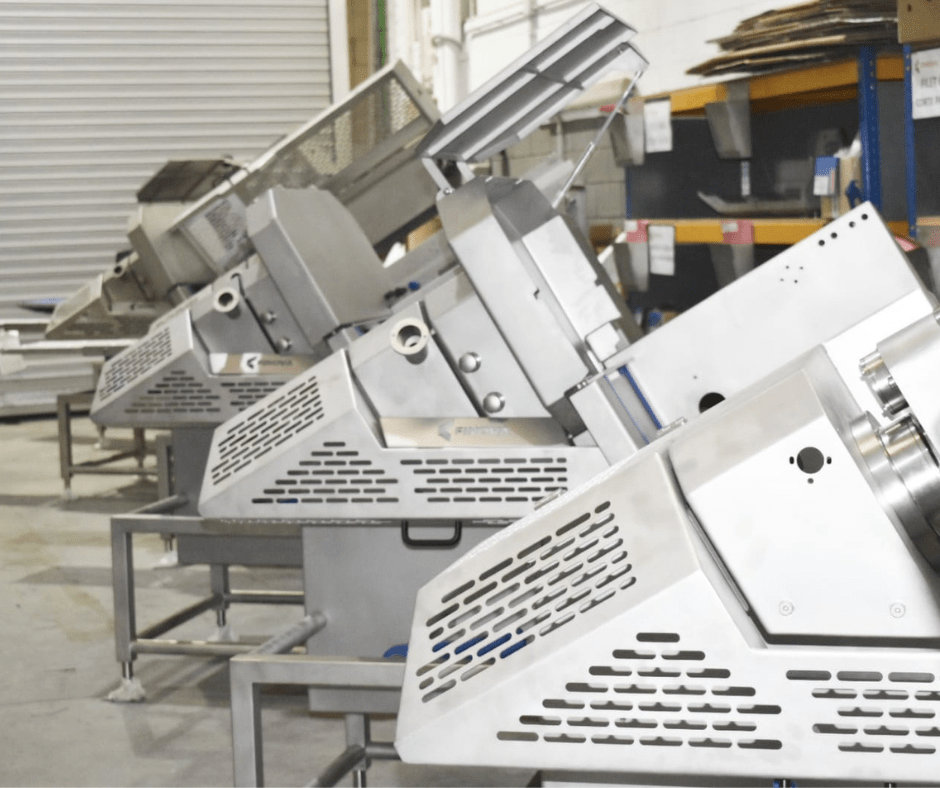

Mass production of SliceFil slicers

The mass production system of our SliceFil slicers allows us to produce batches of 10 or 15 units simultaneously. This production method offers several advantages that improve the efficiency and quality of the manufacturing process.

System advantages

Production efficiency

The mass production system allows for greater efficiency in the use of time and resources, as processes are optimized to produce multiple units simultaneously.

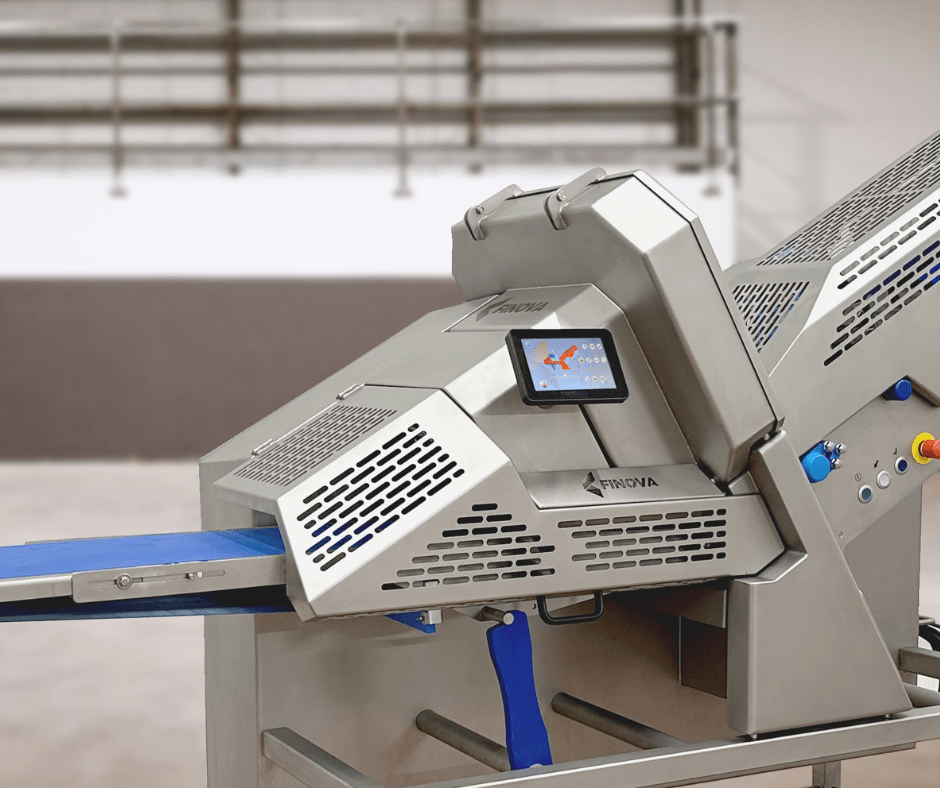

Standardization and quality

By manufacturing in batches, we guarantee that each unit of the slicers maintains a high level of standardization and quality, complying with the established requirements and characteristics.

Cost reduction

Mass production reduces unit costs by allowing us to purchase materials and components in large quantities, we obtain significant discounts that are reflected in the final price of the machine for our customers.

Tight delivery schedules

The ability to produce several units at a time allows for faster delivery to customers. This improves customer satisfaction and responsiveness to market demand, ensuring that orders are fulfilled efficiently and on time.

Resource optimization

Mass production facilitates the optimization of design and labor hours, minimizing non-productive time and maximizing productivity levels. This ensures that available resources are used as effectively as possible.

Continuous improvement

The repetition of processes in mass production allows for continuous improvement. We quickly identify and correct any problems, which optimizes the performance and quality of the slicers.

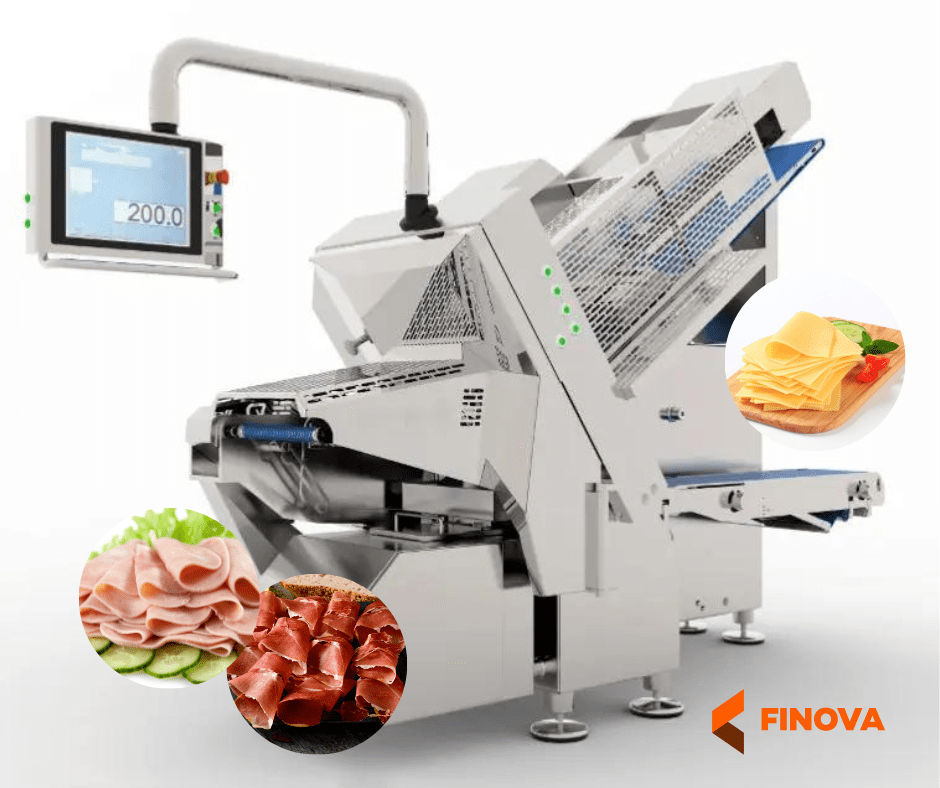

The mass production system of Finova’s SliceFil slicers not only ensures high quality and consistency in each unit, but also offers significant economic, maintenance and logistical benefits. This positions Finova as a leader in efficiency and customer satisfaction in the slicing equipment industry, guaranteeing high quality products at competitive prices and with reduced delivery times.